Welcome to Paratherm

Premier Heat Transfer Fluid Technology

Engineered Fluids

Proven, advanced formulations ideal for your processes, industry, and applications. More choices and better choices in heat transfer fluids based on our 30 years in this business.

Find Out More24/7 Response

Quick, knowledgeable answers on fluid selection. Rapid turnaround on lab tests. Products stocked strategically for faster delivery. 24/7 contact center for emergencies. Just the beginning of Paratherm superior responsiveness.

Learn MoreExpert Support

Technical and engineering experts with decades of real-world indirect heating experience. We know what goes wrong, how to fix it, and how to stop it from happening again. We know heat transfer for your industry (cold) and hot.

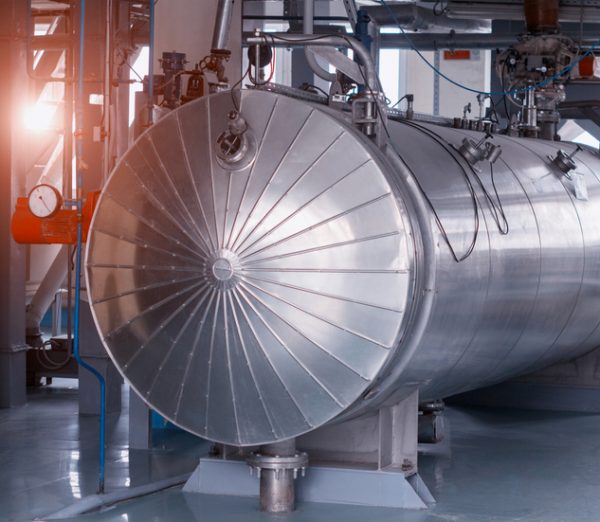

Contact UsHeat Transfer Fluid Technology Backed By Superior Service

Not all heat transfer fluids, or the companies that provide and service them, are created equal. Paratherm offers only the best fluid formulations, then backs them up with proactive services and industry-leading expertise. With hundreds of years of cumulative heat transfer experience, we’ve perfected the art of customer service and the science of heat transfer technology. That’s what our customers say. We invite you to experience our fluid technology and solid service.

We deliver exactly what you need for ongoing reliable performance

From fluid analysis to initial and ongoing training, troubleshooting to technical expertise and documentation, as a thermal heat transfer fluid manufacturer, Paratherm provides more added-value, no-cost services to our customers.

Paratherm Delivers. See how Paratherm is different and better.

Have a big system? Paratherm supplies the best products and services, delivered with expertise. Bulk Shipments are available and customed to fit your schedule.

Industries Served

Paratherm offers more for more industries – for heating, cooling, and temperature transfer

News

-

Bolstering Fire Safety

Edward Cass, Paratherm, USA, explains how the risk of fire in thermal fluid systems can be minimised.

-

Learn how Routine Fluid Analysis Can Extend the life of your system

Routine Testing and fluid analysis is vital to ensure your equipment is in the best possible shape.

-

3 Key Strategies for Maximizing Performance of Heat Transfer Fluids

Ed Cass, MLT I, Paratherm’s Technology Manager, discusses key strategies for increasing your heat transfer fluid performance.